The company has complete production and supporting facilities, including raw material pretreatment area, coil manufacturing area, vacuum casting area, curing and maintenance area and quality inspection center. With these advanced production facilities, the company's annual production capacity reaches 2 million kVA.

High-voltage winding is a critical part of a cast resin transformer, where high manufacturing quality drives the difference.

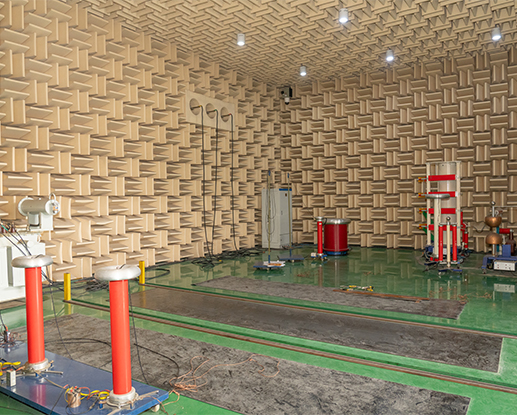

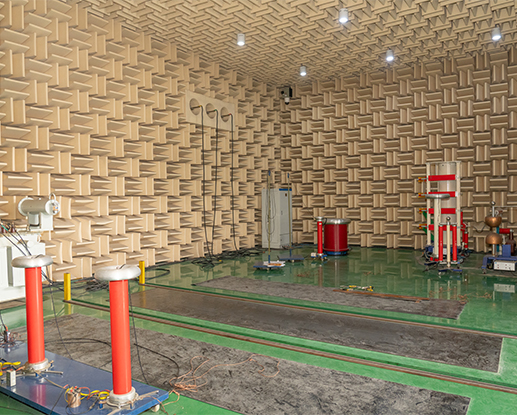

Detong Power Technology assures the total reliability of its product through the use of demanding manufacturing control. High-voltage coils undergo a repetitive impulse test after winding and before casting to verify the absence of dielectric defects. Once the coil passes this test, it is encapsulated under vacuum. After encapsulation, the partial discharge level is measured to confirm the absence of bubbles or gaps, thereby demonstrating the long-term reliability of the high-voltage insulation system.

Every transformer undergoes a detailed individual test and inspection, including all routine tests according to national standards as follows:

(1) Measurement of winding resistance

(2) Measurement of voltage ratio and testing of vector group

(3) Load loss and short-circuit impedance measurement

(4) No load loss and no load current measurement

(5) Separate source voltage withstand test

(6) Induced overvoltage withstand test

(7) Partial discharges measurement

We strictly adhere to industry standards and comply with local product regulations to demonstrate our commitment to quality, safety and environmental responsibility. The relevant certifications we have obtained not only demonstrate our commitment to the high standards of the transformer industry, but also bring confidence and assurance to our customers who work with us.