1. Introduction

Transformers are one of the most critical components in electrical power systems. They operate silently in substations, factories, and transmission networks, stepping voltages up or down to ensure safe and efficient power distribution.

Despite having no moving parts, transformers are not maintenance-free; one of their biggest challenges is heat management. Without adequate cooling, their reliability, efficiency, and lifespan are severely compromised.

2. Sources of Heat in Transformers

2.1 Copper Losses (I²R Losses)

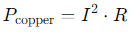

When current flows through the windings, the electrical resistance of the conductors causes Joule heating:

Proportional to the square of the load current.

Main contributor to heating under heavy load conditions.

2.2 Core Losses

Even when the transformer is unloaded, the alternating magnetic flux in the core produces heat.

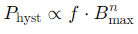

Hysteresis Losses

Due to molecular friction as magnetic domains align and realign with each AC cycle.

Eddy Current Losses

Induced circulating currents in the laminated steel core cause resistive heating.

Minimized by using thin, insulated laminations.

2.3 Stray Losses

Leakage flux induces currents in metallic parts other than the windings and core, producing additional localized heating.

3. Why Excessive Heat is Dangerous

3.1 Insulation Aging

Transformer windings are insulated with materials like cellulose paper and varnish.

Thermal aging law (Montsinger’s Rule): A 6–10 °C rise in operating temperature halves insulation life.

Overheated insulation becomes brittle, leading to dielectric breakdown.

3.2 Oil Deterioration

Oil in oil-immersed transformers:

Acts as a coolant.

Provides dielectric insulation.

Dissolves gases generated by faults.

Excessive heat causes:

Breakdown of oil molecules.

Formation of sludge and acids.

Lowered dielectric strength.

3.3 Structural Damage

Thermal expansion and contraction can loosen clamping structures, deform windings, and lead to short-circuits.

3.4 Efficiency Drop

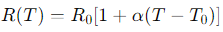

Resistance increases with temperature:

Where α ≈ 0.004 / °C for copper.

This leads to higher losses and more heat — a self-worsening loop.

4. Cooling Requirements in Transformer Design

4.1 Temperature Limits

Standards (IEC 60076, IEEE C57) define permissible temperature rises:

Winding: typically 65 °C rise above ambient.

Oil: typically 55 °C rise above ambient.

4.2 Cooling Performance Factor

Cooling design must match rated load plus overload capability, ensuring stable operation even during peak demand.

5. Cooling Methods

| Code | Method | Description |

| AN | Air Natural | Small dry-type transformers cooled by natural air circulation. |

| AF | Air Forced | Fans push air across windings. |

| ONAN | Oil Natural Air Natural | Natural convection circulates oil; radiators dissipate heat to surrounding air. |

| ONAF | Oil Natural Air Forced | Oil circulates naturally; fans blow air over radiators. |

| OFAF | Oil Forced Air Forced | Pumps circulate oil; fans assist cooling. |

| OFWF | Oil Forced Water Forced | Pumps circulate oil through a water-cooled heat exchanger. |

6. Real-World Case Example

In 2019, a 220 kV transformer in a power substation failed due to inadequate cooling after fan failure. Internal winding temperature exceeded 140 °C, leading to:

Complete breakdown of insulation.

Internal short-circuits.

Catastrophic oil fire.

A $3 million replacement and six months of outage followed. Post-analysis showed that if redundant cooling fans had been operational, the overheating could have been avoided.

7. Design Trade-Offs

Cooling systems add cost, complexity, and maintenance needs. Engineers must balance:

Size vs. cooling method: More cooling allows a smaller transformer core for the same rating.

Noise: Forced cooling adds acoustic noise.

Reliability: Redundant fans/pumps increase reliability but also cost.

8. Conclusion

Cooling is not an optional luxury in transformer design — it is an essential safeguard against failure.

Without it:

Insulation degrades rapidly.

Oil loses insulating properties.

Winding resistance increases.

The transformer risks catastrophic failure.

Efficient cooling ensures long service life, safe operation, and reliable power supply.

1.Types of High Voltage Switchgear The main categories of high voltage switchgear include Air-Insula...

View More1. Working Principle Oil-immersed transformers play a pivotal role in modern electrical power system...

View More1. Advantages of Distribution Dry Type Transformers Distribution dry type transformers have become i...

View More